- Home Page

- Company Profile

-

Our Products

- Briquetting Machines

- Biocoal Briquette Machine

- Sawdust Briquette Machine

- Briquette Press Machine

- Coir Pith Briquetting Machine

- Briquette Machine

- Biomass Briquette Machine

- White Coal Briquette Machine

- Wheat Straw Biomass Briquettes Making Machine

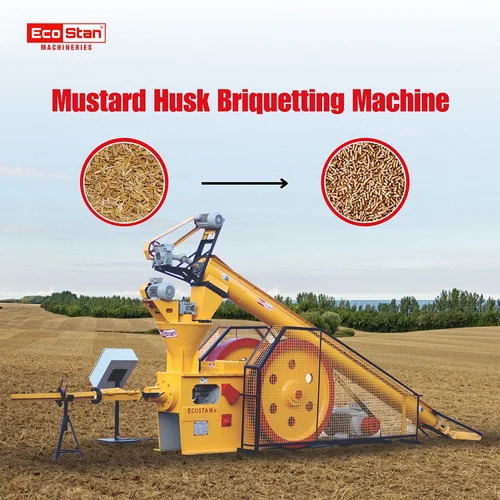

- Mustard Straw Briquetting Machine

- Automatic Biomass Briquetting Plant

- White Coal Biomass Briquette Machine

- Straw Pellet Press

- Rice Husk Biomass Briquette Plant

- Biomass Pellet Press Machine

- White Coal Making Machine

- Ecostan Model 40 Biomass Briquetting Machine

- MSW Briquetting Press Machine

- Wood Chips Biomass Briquetting Machine

- Forest Residues Biomass Briquetting Machine

- Rice Straw Briquetting Machine

- Sawdust Biomass Briquettes Machine

- MSW Biomass Briquette Machine

- Ecostan 40 Briquetting Press Machine

- Soya Husk Briquetting Machine

- Agriculture Waste Briquetting Machine

- Shredder Machines

- E Waste Shredder Machine

- Dual Shaft Industrial Shredders

- Sugarcane Straw Shredder

- Biomass Shredder Machine

- Industrial Waste Shredder

- Bio Medical Waste Shredder

- Municipal Solid Waste Shredder

- Rdf Waste Shredder

- Rice Straw Shredder

- Twin Shaft Shredding Machine

- Sugarcane Straw Shredding Machine

- Municipal Waste Shredding Machines

- Rice Straw Shredding Machine

- Pellet Mill Machines

- Hammer Mills

- Chipper Cum Shredder

- Cow Dung Log Making Machine

- Saw Dust Making Machine

- Industrial Shredder

- Chipper Cum Grinder Machine

- Pneumatic Stone Separators

- Flash Dryers

- Drum Dryer

- Agricultural Shredder

- Bale Unroller

- Briquetting Plant

- Hammer Mill Grinder

- Rotary Drum Dryer

- Pellet Machine

- Vibrating Machine

- Micromax Combo Machine

- Stone Separator

- Briquetting Press

- Agriculture Waste Chipper

- Heavy Duty Agri Waste Chipper

- Briquetting Machines

- More Details

- Contact Us

Briquette Machine

500000.00 - 1600000.00 INR/Piece

Product Details:

- Product Type Briquette Machine

- General Use Biomass, Coal, Charcoal Briquetting

- Material Steel

- Production Capacity 800-2000 kg/h

- Product Shape Cylindrical / Pillow / Custom

- Weight (kg) 1800-3500

- Type Mechanical & Hydraulic

- Click to View more

X

Briquette Machine Price And Quantity

- 1 Piece

- 500000.00 - 1600000.00 INR/Piece

Briquette Machine Product Specifications

- Semi-automatic / Fully automatic

- Briquette Machine

- Alloy Steel

- 15-20 rpm

- Cylindrical / Pillow / Custom

- 1800-3500

- 20 mm - 80 mm

- Steel

- 7.5-30 kW

- Room Temperature

- No

- Blue / Grey / Customized

- 800-2000 kg/h

- 300-600 mm

- Horizontal

- Mechanical & Hydraulic

- High Pressure Compacting

- 220-400 mm

- Biomass, Coal, Charcoal Briquetting

- Water Cooling System

- High output, energy-saving, wear-resistant parts

- Optional

- 380V / 415V / Customized

- 2300 x 1200 x 1750 mm (varies by model)

Briquette Machine Trade Information

- 1 Piece Per Week

- 30 Days

Product Description

Specification

Model No. | Production | Power requirements |

Ecostan 100 | Up to 2500 kg/hr | 91/116 HP |

Ecostan 90 | Up to 2000 kg/hr | 88.5 HP |

Ecostan 70 | Up to 1300 kg/hr | 59 HP |

Ecostan 60 | Up to 1000 kg/hr | 47 HP |

Ecostan 40 | Up to 250 kg/hr | 23 HP |

Product Details

| Briquette Length | 50 mm - 150 mm |

| Automatic Grade | Semi-Automatic |

| Production Capacity | 250 Kg/H |

| Raw Material Processed | Tree Trimming,Coconut Shell |

| Raw Material Mositure | 8 - 13 % |

| Power | 23 Hp |

| Model | Prime 40 |

| Finish Good Diameter | 40 mm |

Versatile Shaping and High Efficiency

Engineered for flexibility, this briquette machine supports a range of output shapes such as oval, pillow, spherical, and custom profiles, catering to diverse biomass, coal, and charcoal briquetting needs. With a customizable feeding system and various roller dimensions, it delivers a robust hourly production capacity between 800 and 2000 kg, suited for industrial scale manufacturing and energy applications.

Energy-Saving and Durable Construction

Combining low power consumption with a robust steel frame and wear-resistant alloy steel rollers, this machine ensures long-lasting service and reduced operational costs. Its fully automatic grease lubrication system keeps the moving parts functioning smoothly, reducing maintenance downtime while maximizing efficiency.

Comprehensive Support and Flexible Installation

Our briquette machines come with a complete installation service, either at site or online, along with ongoing technical support. They are packaged in sturdy wooden crates or custom packaging to ensure safe transport. Customers can order spare parts as needed and opt for PLC control and cooling systems to meet specific operational requirements.

FAQ's of Briquette Machine:

Q: How does the raw material size affect the briquette machine's performance?

A: Optimal performance is achieved when the raw material size is 20 mm and the feeding size is between 10-12 mm, ensuring uniform compaction and minimizing blockages during processing.Q: What shapes and sizes of briquettes can this machine produce?

A: The machine is capable of producing customizable briquette shapes such as oval, pillow, square, spherical, cylindrical, or as per specific requirements, with sizes ranging from 20 mm to 80 mm.Q: When is maintenance required, and what after-sales services are offered?

A: Routine maintenance is minimal due to the fully automatic grease lubrication system. We provide both onsite and online technical support, spare parts upon request, and comprehensive installation services.Q: Where can this briquette machine be installed?

A: This machine is suitable for installation in manufacturing plants and energy & mining facilities. It comes with adaptable voltage and structure options to suit different industrial environments.Q: What is the operating process of this briquette machine?

A: The machine utilizes a roller press molding process; raw materials are fed (20 mm), compacted under high pressure using mechanical or hydraulic action, and formed into desired shapes before automatic discharge.Q: How does the cooling and lubrication system benefit long-term usage?

A: The water cooling system maintains optimal processing temperatures, preventing overheating, while the automatic grease lubrication reduces wear on key components, thereby extending the machine's operational lifespan.Q: What are the key benefits of using this briquette machine in industry?

A: Users benefit from low power consumption, high production output, robust construction, customizable product shapes, and reliable after-sales support. Its durable, wear-resistant build ensures long-term productivity and reduced downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email